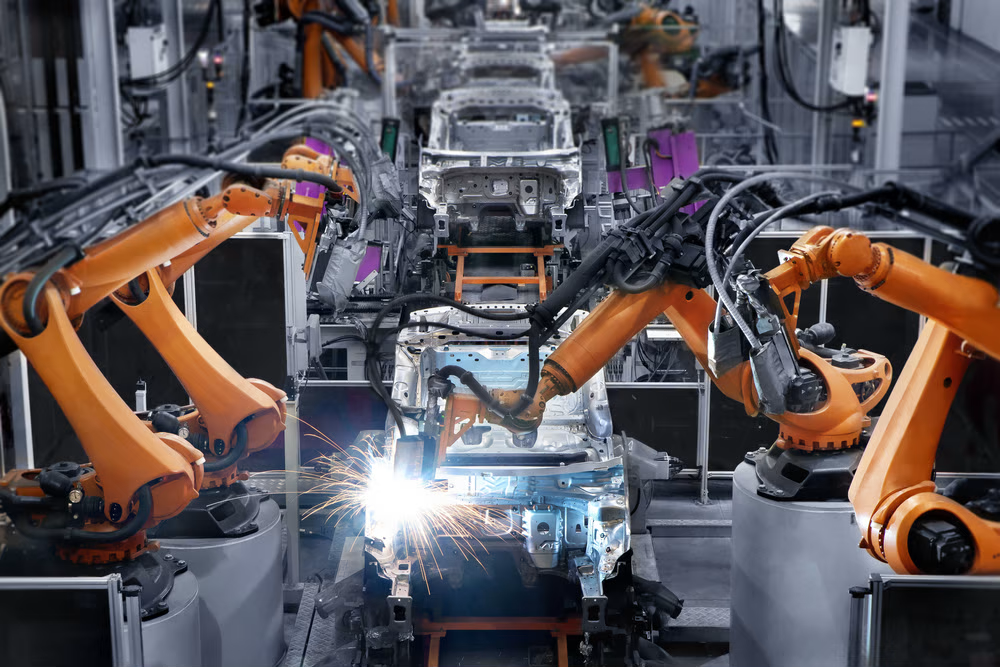

Manufacturing is a realm where efficiency and precision are key requirements in the process of production. Robotic welding systems have been considered as a revolution in the welding industrial process since it is far superior to conventional welding processes in many ways. The benefits of robotic welding automation range from higher productivity, better quality to improving safety in the workshop. The following are ten key reasons why companies should think of automating through the use of robotic welding systems.

- Enhanced Productivity: Robotic welding systems can work without stopping, and this means that there will be increased production when using robotic welding as compared to manual welding. One of the benefits of implementing such systems is that it is possible for them to run for long hours without being exhausted, thus providing a constant level of production, translating into increased overall productivity. It also leads to enhanced profitability for businesses since productivity is a key factor in determining the profitability of an enterprise.

- Precision Engineering: Robotic welding systems are most efficient when it comes to the weld accuracy and consistency of the welds. These systems can use sophisticated sensors and software programming to weld and control the quality of welds and structural strength. Such accuracy of work helps in reduction of rework and ensures that all products meet the set high standards.

- Cost Efficiency: One may argue that the costs of acquiring robotic welding systems are high in the beginning, but the returns will be high in the long run. Cutting out the middleman in the form of a human operator these systems are a long-term cost saver both in terms of materials and labor. Further, the fact that these robots are capable of performing their functions independently also means that there is minimal need for human input, which has a positive impact on the issue of labor expenses.

- Increased Safety: A reduction of risks is a primary concern in any production area, and robotic welding systems are helpful in improving the safety aspect. Some of these systems involve taking the riskiest tasks, for instance, working in areas with high temperatures or in areas where toxic fumes are produced and this reduces the probability of accidents and injuries occurring in the workplace. This not only safeguards the lives of workers but also minimize the risks on businesses in the occurrence of mishaps.

- Flexibility and Versatility: Robotic welding systems are versatile, and can be easily programmed to handle various welding processes and diversity in part configurations. Due to their versatility in handling various tasks at a very short time, these systems are unique in the manner in which they undertake the production processes. If it involves welding small parts or assembling a large structure, robotic welding systems are capable of handling all these tasks.

- Consistent Quality: The quality of the welds formed has to be consistent to ensure that the products manufactured bear the required standards of reliability and performance. Robotic welding systems are also good in offering consistent welds that are not likely to vary much. These systems offer increased control and accuracy of welds since they are programmed to welding specifications and follow specific parameters that cannot be achieved through manual welding.

- Improved Cycle Times: One of the major factors in manufacturing is time, and robotic welding systems are particularly good at minimizing it. These systems offer high welding speeds and proper workflow organization, so it takes them significantly less amount of time to perform welding compared to manual methods. As a result of this fast production method, various businesses are able to produce their goods quickly because of strict time limits and customer demands.

- Scalability: In any economy, it is significant that companies become scalable as they progress through their development cycles. Robotic welding systems are flexible in production processes; it means that companies can increase the production of a certain part while increasing the level of employment of robotics. These systems are capable of changing in order to fit the current demand; be it through increasing the batch sizes or the addition of new products in the line.

- Integration with Industry 4.0: Automated welding systems are crucial components of the transition towards the industrial revolution 4.0, improving operational efficiency by focusing on connectivity and data analysis in production lines. These systems are highly interconnected with other smart technologies like IoT and cloud based platforms to provide real-time monitoring, predictive maintenance and adaptability of control which can boost up the efficiency and innovation.

- Competitive Advantage: Competition has become an essential aspect of business operations whereby businesses need to establish a unique selling proposition. Robot welding is a major focus for advancing technology in industries as it offers companies an enhanced opportunity to produce quality products at a faster rate and with less money. This goes in line with the fact that through the use of advanced automation technology, organizations can be able to adapt themselves as preferred leaders within the market.

To sum up, we have to note that the investment in robotic welding systems is not only about adopting the new technology; it is about the future of your manufacturing processes. There are numerous advantages of robotic welding automation ranging from productivity, accuracy in engineering and production to cost control and competitive edge. In utilizing these modern systems, companies have the capacity to enhance efficiency and quality of products manufactured in the context of the current global manufacturing environment.